| Sign In | Join Free | My components-electronic.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My components-electronic.com |

|

Brand Name : Bicheng

Model Number : BIC-052.V1.0

Certification : UL, ISO9001, IATF16949

Place of Origin : CHINA

MOQ : 1PCS

Price : USD9.99-99.99

Payment Terms : T/T

Supply Ability : 5000PCS per month

Delivery Time : 8-9 working days

Packaging Details : Vacuum bags+Cartons

Base material : Rogers' RO4003C

Layer count : 4-layer

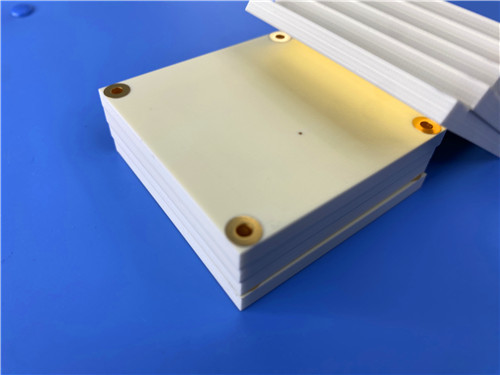

PCB thickness : 4.8mm

PCB size : 60mm x 60mm per piece, with a tolerance of +/- 0.15mm

Copper weight : 1oz (1.4 mils) for both inner and outer layers

Surface finish : Electroless Nickel Immersion Gold (ENIG)

This high-performance 4-layer PCB is engineered using Rogers' RO4003C material—a woven glass reinforced hydrocarbon/ceramic laminate—to deliver exceptional electrical performance and manufacturability, making it ideal for high-frequency and RF applications. Below is a comprehensive overview of its specifications, construction, and key attributes:

PCB Construction Details

| Parameter | Details |

| Base Material | Rogers' RO4003C, a proprietary woven glass reinforced hydrocarbon/ceramic material combining PTFE/woven glass electrical performance with epoxy/glass manufacturability. |

| Layer Count | 4-layer rigid PCB, optimized for complex high-frequency signal routing and multi-layer functionality. |

| Board Dimensions | 60mm x 60mm per piece, with a tolerance of +/- 0.15mm for precise assembly fit. |

| Minimum Trace/Space | 4/5 mils, enabling fine signal routing critical for high-frequency operations. |

| Minimum Hole Size | 0.4mm, accommodating small components and ensuring reliable interconnections. |

| Finished Board Thickness | 4.8mm, providing robust structural integrity for demanding applications. |

| Finished Copper Weight | 1oz (1.4 mils) for both inner and outer layers, ensuring low resistance and efficient current handling. |

| Surface Finish | Electroless Nickel Immersion Gold (ENIG), offering excellent corrosion resistance, solderability, and stable electrical contact. |

| Silkscreen | Black silkscreen on the top layer for clear component labeling; no silkscreen on the bottom layer. |

| Solder Mask | No solder mask on either top or bottom layers. |

| Special Features | Includes countersunk holes (conical, 90-degree) for secure mounting. |

| Quality Assurance | Undergoes 100% electrical testing prior to shipment, ensuring faultless performance and compliance with design specifications. |

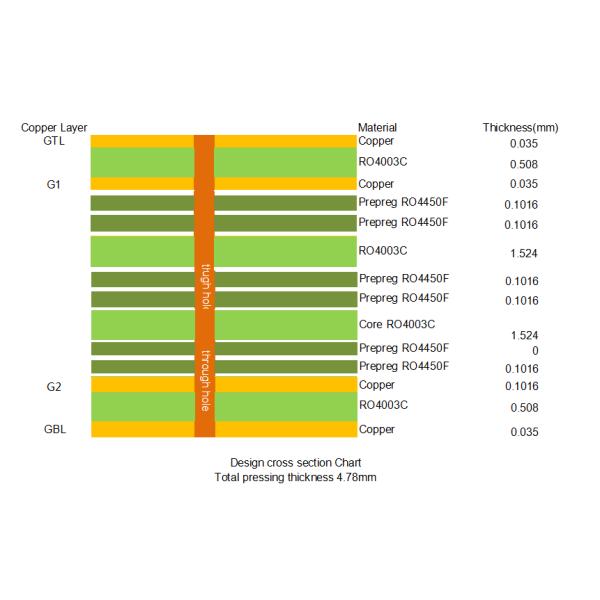

PCB Stack-up

The 5-layer rigid PCB features a precise stack-up designed for optimal signal integrity and thermal stability:

| Layer | Specification |

| Copper Layer 1 | 35 μm, providing a solid conductive path for high-frequency signals. |

| Rogers 4003C Core | 0.508mm (20mil) thickness, forming the top insulating layer with stable dielectric properties. |

| Copper Layer 2 | 35 μm, facilitating intermediate signal routing. |

| Prepreg RO4450F (x2) | 0.204mm total thickness, ensuring reliable adhesion between layers. |

| Rogers 4003C Core | 1.524mm (60mil) thickness, serving as a central insulating layer. |

| Prepreg RO4450F (x2) | 0.204mm total thickness, maintaining layer bonding. |

| Rogers 4003C Core | 1.524mm (60mil) thickness, enhancing structural rigidity and insulation. |

| Prepreg RO4450F (x2) | 0.204mm total thickness, ensuring layer integrity. |

| Copper Layer 3 | 35 μm, supporting additional signal and power routing. |

| Rogers 4003C Core | 0.508mm (20mil) thickness, forming the bottom insulating layer. |

| Copper Layer 4 | 35 μm, mirroring the top layer for balanced electrical performance. |

Artwork and Standards

Artwork Supplied: Gerber RS-274-X, the industry-standard format for PCB manufacturing, ensuring compatibility with production processes.

Quality Standard: Manufactured to IPC-Class-2 specifications, guaranteeing high quality and reliability for general and high-frequency electronics.

RO4003C Material Overview

Rogers' RO4003C is a woven glass reinforced hydrocarbon/ceramic laminate that combines the electrical performance of PTFE/woven glass with the manufacturability of epoxy/glass. It is available in configurations using 1080 and 1674 glass fabrics, all meeting the same electrical performance standards.

Unlike PTFE-based materials, RO4003C requires no special through-hole treatments or handling procedures, simplifying manufacturing. It is non-brominated and not UL 94 V-0 rated.

Key Features of RO4003C

Dielectric Constant: 3.38 +/-0.05 at 10GHz, ensuring consistent signal propagation.

Dissipation Factor: 0.0027 at 10GHz and 0.0021 at 2.5GHz, minimizing signal loss across frequencies.

Thermal Coefficient of Dielectric Constant: +40 ppm/°C, maintaining stability over temperature ranges.

Thermal Conductivity: 0.71 W/m/°K, enabling efficient heat dissipation.

CTE: X-axis: 11ppm/°C, Y-axis: 14ppm/°C, Z-axis: 46ppm/°C, ensuring dimensional stability and compatibility with copper.

Moisture Absorption: 0.06%, maintaining performance in humid environments.

Tg: >280°C (536°F), ensuring stable expansion characteristics during processing.

Benefits of the PCB

Ideal for Multi-Layer Constructions: RO4003C’s properties support complex multi-layer board designs, critical for high-frequency applications.

Cost-Effective Manufacturing: Processes like FR-4 at a fraction of the cost of conventional microwave laminates, reducing production expenses.

High-Volume Compatibility: Designed for performance-sensitive, high-volume applications without compromising on quality.

Reliable Through-Holes: Low Z-axis CTE ensures reliable plated through-hole quality, even in severe thermal shock conditions.

Dimensional Stability: CTE similar to copper enhances stability, making it suitable for mixed dielectric multi-layer boards.

Typical Applications

This PCB is well-suited for:

-Cellular Base Station Antennas and Power Amplifiers

-RF Identification Tags

-Automotive Radar and Sensors

-Low-Noise Blocks (LNB's) for Direct Broadcast Satellites

Availability: This PCB is available for worldwide shipping, ensuring accessibility for global manufacturing and project requirements.

|

|

Rogers RO4003C PCB Board 4-Layer with 60mm x 60mm Size and 4.8mm Thickness for High-Frequency Applications Images |