| Sign In | Join Free | My components-electronic.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My components-electronic.com |

|

Brand Name : Bicheng

Model Number : BIC-332.V1.0

Certification : UL, ISO9001, IATF16949

Place of Origin : CHINA

MOQ : 1PCS

Price : USD9.99-99.99

Payment Terms : T/T

Supply Ability : 5000PCS per month

Delivery Time : 8-9 working days

Packaging Details : Vacuum bags+Cartons

Base material : Rogers RO4003C Low Profile (LoPro)

Layer count : 2 layers

PCB thickness : 0.65mm

PCB size : 64mm x 68.4mm per piece (1PCS)

Silkscreen : White

Solder mask : Green

Copper weight : 1oz (1.4 mils) for outer layers

Surface finish : Silver underplating + Gold plating

This two-layer PCB is meticulously crafted for high-frequency radio frequency (RF) and high-speed digital applications. It utilizes Rogers RO4003C Low Profile (LoPro) material, a hydrocarbon ceramic laminate featuring proprietary reverse-treated foil technology. This combination enables the PCB to achieve superior signal integrity, minimize conductor losses, and ensure cost-efficient manufacturing processes.

PCB Specification

| Parameter | Details |

| Base Material | Rogers RO4003C Low Profile (LoPro) – Hydrocarbon ceramic laminate with reverse-treated foil |

| Layer Count | 2-Layer (rigid structure) |

| Board Dimensions | 64mm x 68.4mm per piece (1PCS) |

| Minimum Trace/Space | 5 mils (trace) / 5 mils (space) |

| Minimum Hole Size | 0.3mm |

| Vias | No blind vias; via plating thickness = 20 μm |

| Finished Board Thickness | 0.65mm |

| Finished Copper Weight | 1oz (1.4 mils) for outer layers |

| Surface Finish | Silver underplating + Gold plating |

| Silkscreen | White silkscreen on top layer, no silkscreen on bottom layer |

| Solder Mask | Green solder mask on top layer; no solder mask on bottom layer |

| Quality Assurance | 100% electrical testing conducted prior to shipment |

Rogers RO4003C Low Profile Material Introduction

Rogers RO4003C Low Profile (LoPro) is a game-changing hydrocarbon ceramic laminate that redefines cost-effective high-performance PCB design. Its core innovation lies in proprietary reverse-treated foil technology: this allows the foil to bond directly to standard RO4003C dielectric, creating a laminate with drastically reduced conductor loss—while preserving all the desirable attributes of standard RO4003C (e.g., low dielectric loss, FR-4 process compatibility).

Unlike traditional high-frequency materials (e.g., PTFE-based laminates) that require specialized via preparation (e.g., sodium etch), RO4003C LoPro works with standard epoxy/glass (FR-4) fabrication processes. This eliminates extra manufacturing steps, slashes costs, and makes it accessible to most PCB factories. It’s designed to bridge the gap between high-performance RF materials and cost-effective digital substrates, making it ideal for mixed-signal applications.

RO4003C Low Profile Key Features

| Feature | Specification |

| Material Composition | Hydrocarbon ceramic laminate with reverse-treated foil |

| Dielectric Constant (Dk) | 3.38 ± 0.05 at 10GHz/23°C |

| Dissipation Factor (DF) | 0.0027 at 10GHz/23°C |

| Thermal Performance | - Decomposition Temp (Td): >425°C- Glass Transition Temp (Tg): >280°C (TMA) |

| Thermal Conductivity | 0.64 W/mK |

| Coefficient of Thermal Expansion (CTE) | - X-axis: 11 ppm/°C- Y-axis: 14 ppm/°C- Z-axis: 46 ppm/°C (-55 to 288°C) |

| Process Compatibility | Lead-free process compatible; standard FR-4 fabrication compatible |

| Additional Attribute | CAF (Conductive Anodic Filament) resistant |

Material Benefits

RO4003C LoPro’s properties translate to tangible advantages for the PCB, solving key challenges in high-speed/RF design and cost-sensitive manufacturing:

Ultra-Low Insertion Loss: Reduced conductor loss enables reliable operation beyond 40 GHz.

Minimized Passive Intermodulation (PIM): Low PIM levels prevent signal distortion in high-power RF systems.

FR-4 Process Compatibility: Uses standard fabrication workflows (no specialized via treatment) to cut manufacturing costs and lead times.

Thermal Resilience: High Tg (>280°C) and Td (>425°C) withstand lead-free soldering and high-temperature operating environments.

Copper-Matched CTE: X/Y-axis CTE (11/14 ppm/°C) matches copper, eliminating solder joint stress during thermal cycling.

CAF Resistance: Protects against conductive anodic filament formation.

Design Flexibility: Supports both multi-layer PCBs (for complex digital circuits) and 2-layer designs, adapting to diverse project needs.

Some Typical Applications

- Digital applications such as servers, routers, and high speed back planes

- Cellular base station antennas and power amplifiers

- LNB’s for direct broadcast satellites

- RF Identification Tags

|

|

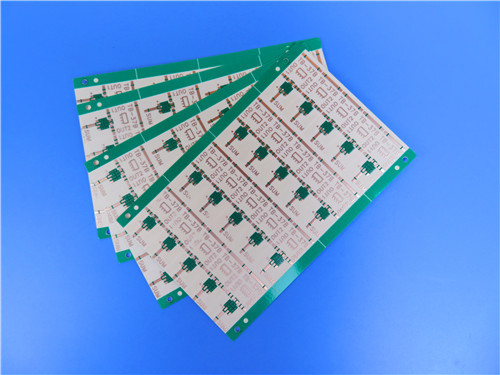

LoPro RO4003C PCB Rogers 20.7mil Substrate Double-sided Images |